Manufacturing experience with hundreds of customers

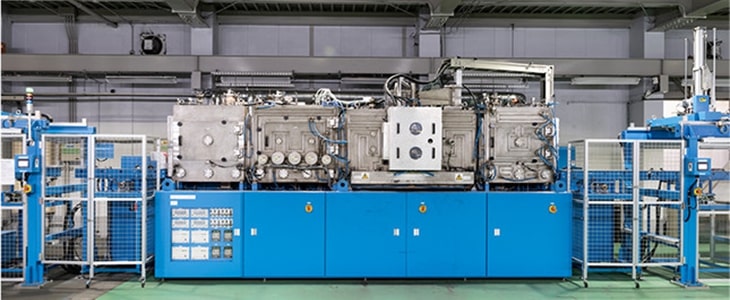

Our branches in Japan have manufactured and designed PVD coating machines and offered coating processing since 1985. We offer high quality coating services through the accumulated experience of hardware and software knowledge in regards to PVD processing using Arc Ion Plating. For this reason, we are flexible with various customer demands, quick on feedback and active on continuous improvement.

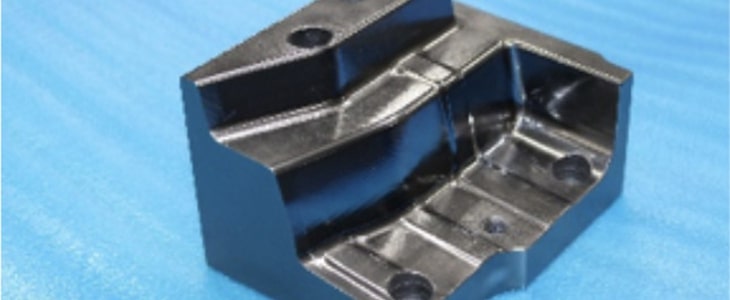

Surface treatment involves the transformation of the base surface properties through heat treatment or vapor deposition.

The change of properties enables characteristics including wear resistance, corrosion resistance, oxidation resistance, sliding property, and water repelling property that was not present in the base material surface.

For production molds, surface treatment improves the lifespan, increasing productivity, reducing mold costs and friction.

Manufacturing and sales of coating devices, development of new fields

All of our coating machines have been designed and built in-house by our branches in Japan.

We provide PVD coating contract services, and we are also working on development further into new fields. Additionally, our branches in Japan also provide contract-based heat treatment processing, PVD coating device manufacturing and sales, and system sales. Our close partnership with them has allowed us to benefit from their expertise gained in previous projects such as heat treatment furnace manufacturing and sales and CVD coating contract processing.

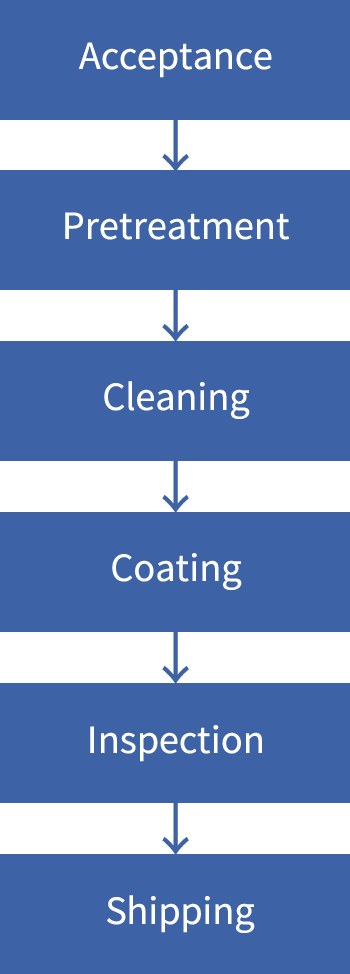

We receive products and check the requirements from customers.

For PVD coating, after confirming the surface condition suitable for coating the surface is improved if necessary

and the cleaning process and PVD coating are performed.

After that, we check the appearance, the operation of the processing furnace,

the film thickness and adhesion of a test piece, and pass or fail judgment before shipping.

Industry leader in PVD coating market size

Our technology, which is positioned at the top of the PVD coating market scale, is used by mold

and cutting tool makers who make shapes (materials), and come to us for PVD coating contracting

to provide the best products for customers.

Therefore, we can make optimal proposals based on our experience and knowledge of heat treatment,

CVD coating, and PVD coating among many achievements.

In addition, we have the expertise to recoat products after use, consider the use case, and make suggestions for the optimal coating.

Different elements have different properties.

It varies depending on the element, such as strength against abrasion, friction coefficient, and rust resistance.

Different films made using the same elements will result in different properties based on the makeup of the film.

Once we receive your parts that have been put to use, we have the capability to offer the best coating solutions depending on the state of the part due to our extensive experience.

and then come to us so we can process and PVD coat their parts.

We are positioned as one of the leading companies for PVD coating industry market scale.

SEAVAC is rapidly improving our systems, due to setting up in-house development

An integrated system for ordering, process management, quality records, and sales management specialized in the hard coating industry, as well as device manufacturing management, regular equipment maintenance, nonconformity, complaints, corrective action records, device error reports, internal audits, sales reports, purchasing management, proposals/settlement are developed in-house.

Therefore, our development strength can quickly improve the system according to the demands of in-house system users.