from the existing PVD Coating for higher hardness, heat resistance and lubricity. Superior wear resistance contributes to longer life.

It is also suitable for die molds with tight dimensional tolerances.

corrosion resistance, and slidability. The component elements are stable and may be used as a base for other coatings to prevent corrosion.

Advanced metal surface treatment

Before WPC and lapping After WPC and lapping

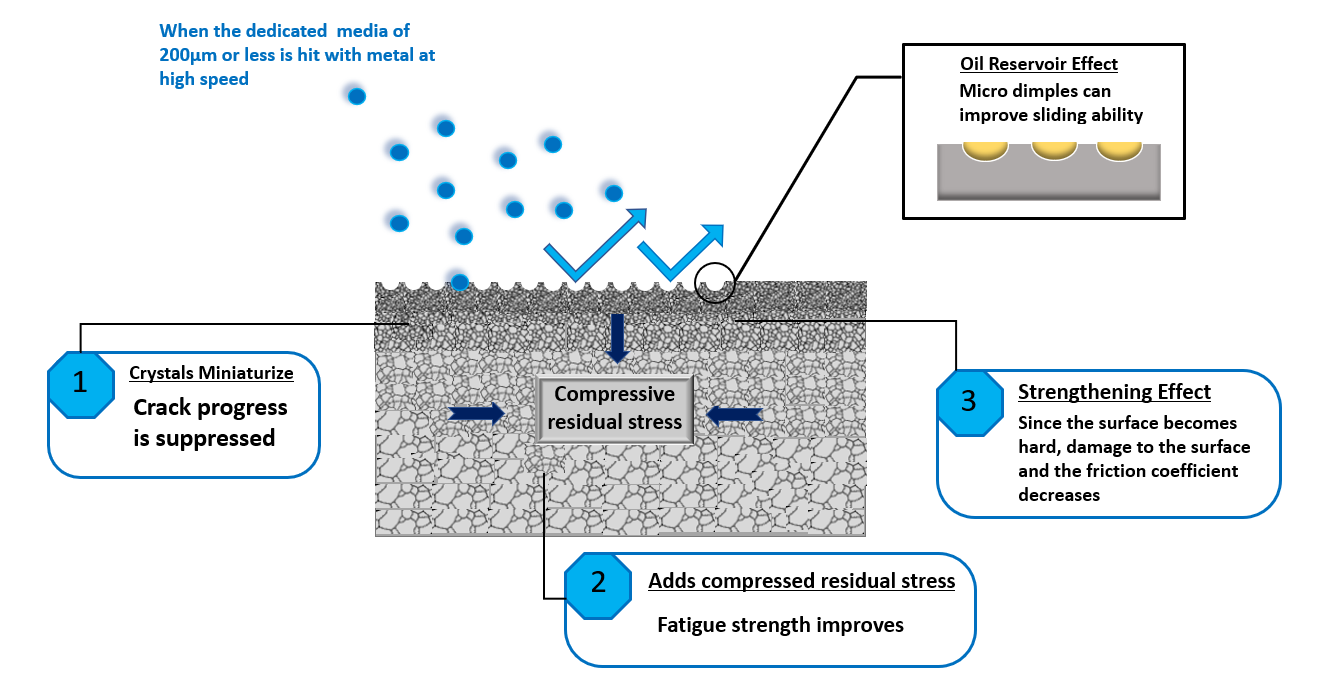

What is WPC?

WPC is a metal surface treatment process that was developed in Japan. WPC can improve the hardness, fatigue strength, and residual compressive stress of metal products by injecting high-speed dedicated media with the size of 200μm or less to the targeted surface. Due to the extremely small mass of the media, WPC does not damage the surface or change the dimensions.

Why WPC before coating?

Due to the effect of WPC, the hardness of the product’s surface layer to a depth of 10 μm will be improved by 1.5 times, thus maximizing the potential of the coating. There will be lapping treatment after WPC to restore the glossiness of the product that was lost due to WPC.

Stripping (coating film removal) of CVD processing and PVD process are provided by SEAVAC.

In particular, PVD processing is performed at temperatures below 500℃,

reducing thermal effects to the base metal, and also reducing the film cost by film removal reprocessing before the base material is severely damaged.